Some points of repairing Jaw crusher spare parts

- 19 Feb 2026

- 2536 times watched

1.Points of repairing moving shaft

Pay special attention to the following points during the maintenance of the journal shaft: in the case of mechanical strength, some of the worn journals are turned and then nested. The important thing is to restore the original fit size.

It is also necessary to pay attention to the use of certain technical measures to weld the welded shafts that have been worn. It is also necessary to use turning and then restore the original matching size. Repairing using vibration welding and metallization is also an important maintenance method.

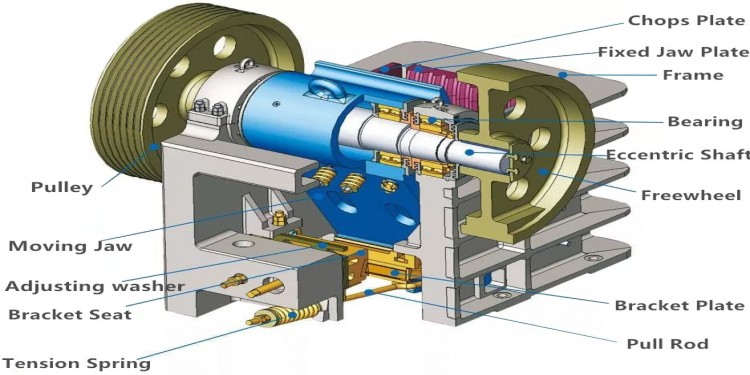

2.Points of repairing eccentric shaft

The eccentric shaft of the jaw crusher should be paied attention to the following points during the maintenance process: according to the actual wear condition of the parts, the corresponding repair method should be selected, and the turning or scraping repair method should be adopted. If the repair process is finished, the journal is slightly weaker. If it is smaller than the original fit size, then a new plain bearing should be made.

In special cases, the original fit size can be restored by nesting after the original journal turning, and repairing by vibration welding and metal spray is also an important method.

3.Points of repairing eccentric shaft sliding bearing

The repair of the bearings in the machine is largely determined by the change in the limits of the gap and geometry. If the bearing is not severely worn, it can be adjusted by the padding method. The change in the tip clearance can extend the operating time of the machine.

However, if the loss is serious, it must be repaired immediately. The method of repairing a plain bearing is generally a simple repair and turning process based on local defects.This type of machining is generally reliable, and all re-casting or stratified gas welding is required for some severely damaged areas.

4.Points of repairing tie rod

During the working process, the rods may crack, break and the bearing hole deviate, the groove of the support pad wears or wears away. When the rod fails and the machine fails to operate, take appropriate repair measures to restore it to normal. Working status. The repair of the connecting rod generally adopts two methods of direct welding and reinforcing steel plate welding, and should be selected according to actual conditions.

Maintenance management plays an important role in the overall operation of the jaw crusher. It is necessary to carry out daily maintenance and repair according to the specific conditions to achieve the optimal performance of the equipment.

Leave us a message