Factors affecting the service life of the cone gyratory crusher eccentric sleeve

- 21 Feb 2026

- 1614 times watched

The gyratory crusher has the advantages of uniform broken particles and high crushing efficiency. It is very widely used. In actual production, the ore particle size varies, and the load non-uniformity is more prominent. Rotary crushers are often short-lived due to premature failure of the eccentric sleeve, which not only increases maintenance costs, but also affects production line production. Here are the factors that affect the life of the eccentric sleeve.

1.Coordination situation

A clearance fit is used between the outer cylindrical surface of the eccentric sleeve and the sleeve of the base.Usually, the tolerance band of the outer cylindrical surface of the eccentric sleeve is d4.If the fit is too tight, the eccentric sleeve is easily stretched during the operation of the gyratory crusher.Conversely, if the fit is too loose, an impact load is likely to occur during the operation of the gyratory crusher.

2.Uniformity of mounting clearance between the base and the lower frame, the lower frame and the upper frame

The eccentric sleeve is mounted on the base, and the upper end of the moving cone is mounted on the upper frame body, and the base, the lower frame and the upper frame are connected by pins. If the gap between the base and the lower frame, and the gap between the lower frame and the upper frame are not uniform, the offset of the tapered sleeve during operation will be inconsistent, and the eccentric sleeve will generate additional load.

3.lubricating oil

In actual production, due to the failure of the seal, the dust enters the oil pool from the bottom of the moving cone, causing the lubricating oil to be contaminated. Impurities wear as the oil flows onto the eccentric sleeve, causing wear on the eccentric sleeve.

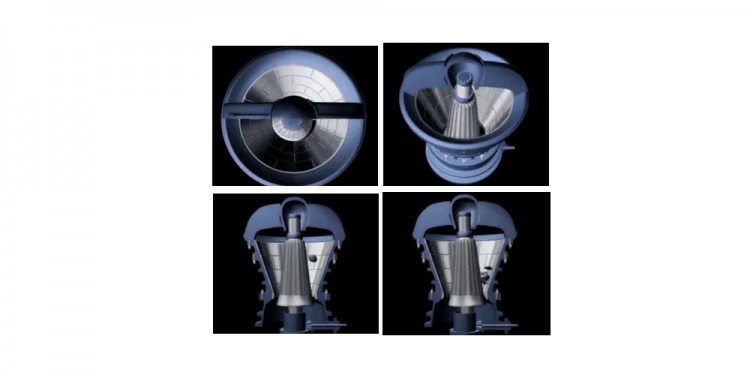

4.Casting quality of eccentric bus alloy

The casting quality of the eccentric bus alloy has a certain influence on the service life of the eccentric sleeve.In order to prevent the bus alloy from falling off abnormally, the "dove tail groove" and "hole" (as shown in the figure) are usually designed on the eccentric sleeve to integrate the bus alloy inside and outside the eccentric sleeve and inside the eccentric sleeve.In the casting process, if the bus alloy cannot be integrated, the bonding force of the bus alloy is weakened, causing the bus alloy to fall off when subjected to an excessive impact load.

Leave us a message